My Wish List

The Craft Of Rum

THE SECRETS OF BUNDY RUM

Rum making is a serious business, but it’s also a secret business. Only those who have

made it this far are allowed to take a peek inside the Bundaberg Rum distillery and

discover the magic of rum making for themselves.

(Also, we made a copy of the keys while nobody was looking. That helped.)

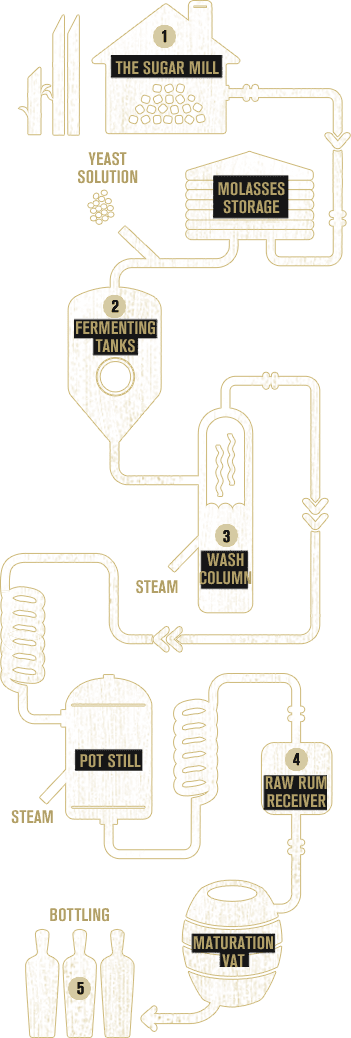

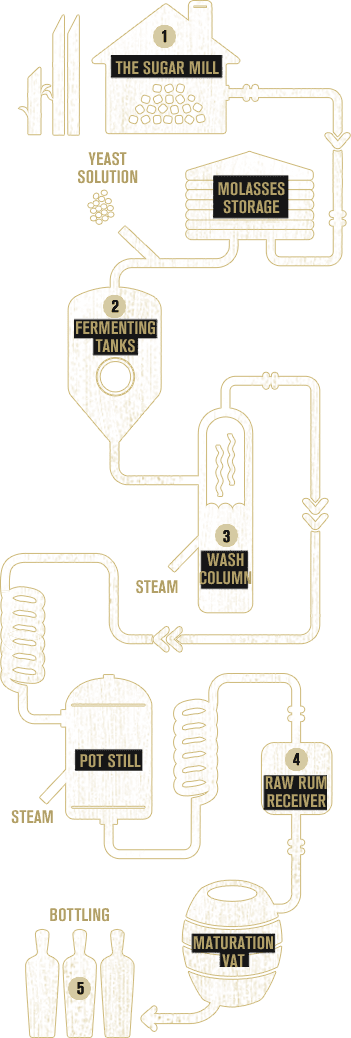

- Molasses

Ah, sweet molasses. Mother nature’s cast-offs are our gain, because molasses is what happens when you process sugar cane into sugar. Thick, sludgy and black, raw molasses is delightful, but probably not something you’d take home to meet your mother. That’s why we spruce it up and clean it real good, a process we call ‘clarification’.

Every year from June to December, we pump the equivalent of 4 Olympic swimming pools full of molasses in this way. It comes through underground pipes directly from the sugar mill cross the road. After this, the molasses has its passport stamped, leaves the distillery and heads for the fermenting tank.

- Fermentation

To make rum you need three things; molasses, water and yeast. Our yeast’s official name is ‘Saccharomyces Cerevisae’, by the way, for all you playing trivia at home. We cultivate our own here, which take about 36 hours for a batch. Once that’s ready it joins the molasses and water for a cruisy two-day stay in our fermentation tanks. This gets us to about 8% alcohol, and then it’s off to be distilled.

- Distillation

Distillation is where most of the science happens in the making of rum. There are two rounds here, the first involving the fermented mixture being pumped into a giant wash column and having a steam room treatment to eliminate by-product. The second is similar, but now it’s in a pot still that looks a bit like a kettle. Only the best portions of the vapours are kept, which are fondly known as the ‘heart cut'. These condense into raw rum.

- Maturation & Ageing

The raw rum, now at 78% alcohol, is also called ‘Immature Rum’ and we all know that some day it has to grow up. This happens in maturation, where the raw rum is transferred over using steel pipes and kept in our Appalachian Range white oak wooden vats, for a minimum of two years. The flavour and colour comes from the tannins in the timber, which slowly seeps in over time. It’s then blended with pure demineralised water down to its bottling strength.

Not all rums are created equal. Some will depart here to become Bundy Spiced rum or be aged further in small barrels to become part of the Master Distillers' Collection range.

- Bottling

We can pump out 120 bottles per minute on our fancy new bottling line down in Sydney, should you be so inclined. If it's made it this far, that molasses has finished its transformation into Cane Champagne. After a quick wash, a fill and a shiny new cap, that bottle is off to your local bottle shop. Or better yet, you can click here and order one right now.